You may or may not realise it but you are presented with thermal printed products almost every single day – depending on how regularly you go out shopping of course.

It is one of the most popular printing techniques used by retailers with receipt printers, you might even have a piece of thermal print sitting in your pocket as you read this article!

This great inkless printing method has been around for decades in various forms and is still widely used today which is why we’re going to share the mechanics involved with direct thermal printing and how it gained its fame with a helping hand from technology pioneers like Nintendo.

How Thermal Printing Works

There are two types of thermal printing – neither of which require the application of ink like an inkjet or lithographic printer. One method, known as thermal transfer printing, involves the use of a heat-sensitive ribbon to create an impression on paper like a heated typewriter. The other is named direct thermal printing.

Direct thermal printing involves the application of heat from a thermal printhead to substrate that has been coated with a solidified chemical mixture of a colourless dye and a matrix (Wikipedia).

To explain this print technique as clearly as possible we will describe the process of direct thermal printing within receipt printers.

Receipt Printers

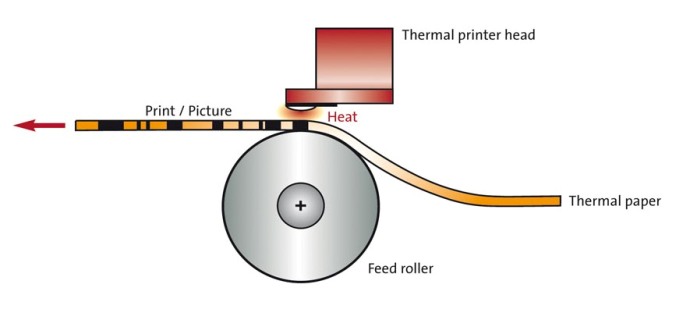

In receipt printers the coated paper is loaded as a roll and fed through a slot that passes it between a rubber roller and the thermal head. The printhead contains many dots, similar to a dot matrix printer, which quickly heats specified areas of the paper as it passes over, using dot formations to produce letters and graphics.

A chemical reaction occurs within the paper’s coating between an acid (octadecylphosphonic acid) and the dye as the matrix reaches a temperature above melting point, producing a black colour.

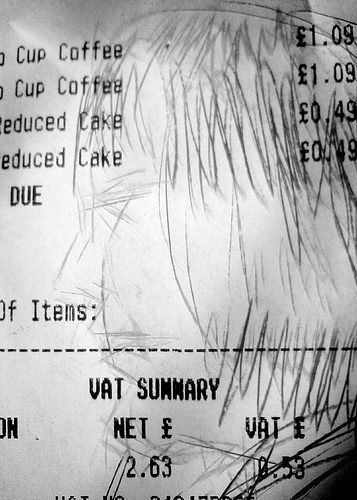

This process happens so quickly that it is unnoticeable to the human eye, however, you can witness the effects of heat on thermo-sensitive paper yourself by running a blunt object across the face of a printed receipt – friction is created between the object and the paper, generating enough heat for the chemical reaction to occur and resulting in a black line.

The heat applied by a thermal printhead is focused in dotted patterns, which is why a receipt printer is able to produce readable text and graphics. If, however, a receipt is exposed to intense UV heat or other high temperatures that cause the reaction to occur then the readability of the printer-generated deteriorates – the main drawback of this print method.

Uses of Thermal Printing

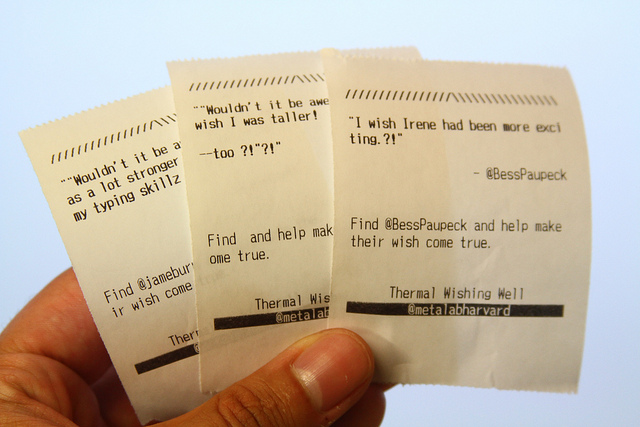

We’ve already identified that thermal printing is commonly used in shop receipt printers, however, there are a few other uses for this type of print that you might not know about:

Nintendo’s Game Boy Printer

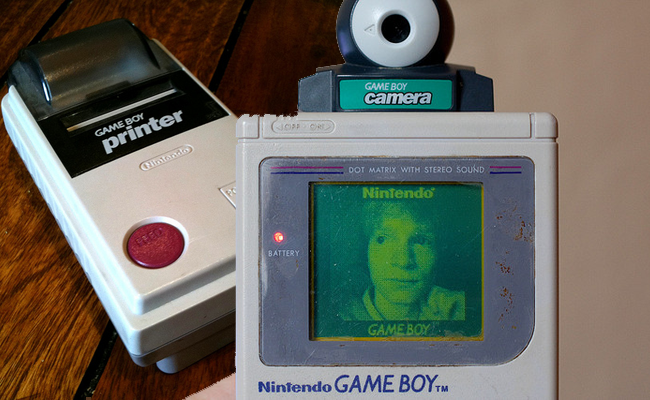

Nintendo’s Game Boy was one of the earliest gaming consoles that allowed users to print out graphics and text directly from gameplay using the Game Boy Printer. Released in 1998, this miniature thermal printer allowed console owners to print stills from later games, such as Pokemon, but it was primarily intended facilitate the Game Boy Camera which was released in the same year.

The combination of the Game Boy camera and printer allowed users to capture very basic dot matrix-style photos and print them onto thermo-sensitive stickers using the direct thermal printing method.

Here’s a video showing the Game Boy printer in action:

The print quality was very poor compared to current day standards, however, for 1998 this was an impressive system unlike any other that allowed people to snap and print on the go.

Other Uses of Thermal Printing

- Electrocardiography (ECG) machines, used by hospitals to record the rhythm of a patient’s heart, used direct thermal printing long before digital recording techniques were created.

- Portable print on demand labelling machines are used by some packaging companies to produce barcodes and other information quickly whilst on the go.

- Point Of Sale (POS) and wireless receipt printers, manufactured by companies like Epson, use thermal printing because of its quick speed and low cost.

- Early fax machines used thermal printing, however, they were replaced by common inkjet printers because of their longer lifespan compared to thermal print.

Summary

To summarise this explanation of direct thermal printing there are 5 key points to remember:

- A thermal printhead is required to apply heat to the thermo-sensitive paper

- The paper is coated with a chemical layer that contains a colourless dye and a matrix

- Thermo-sensitive paper has a chemical reaction that turns black when exposed to heat

- The printhead emits heat in dot matrix patterns to form text and graphics

- Thermal prints can deteriorate over time if stored in a heated environment

If you enjoyed this article and want to read about other printing methods that involve heat, have a read of our article on thermographic printing.

Interesting, a lot to think about.

Oh yes, our early printers where absolute miracles to us but the quality left a lot to be desired.

Inkless Printing technology is mainly developed by Zink and Xerox. Zink is also using the thermal printing method.

It is done by similar methord. But there are 3 layer coated in the paper (Specially made by zink and known as zRoll) and it is color printer.

what i would give to have another gameboy printer.

My ZX-81 had a thermal printer. It seemed miraculous then but it printed on paper 5cm wide and didn’t look very good. A couple of years later dot matrix printers became affordable and were a great improvement.

Great Article. But the statement that “cost is less” is not entirely true. Compared to most inkjet and laser printing considering ink cost, hardware cost and paper cost for standard A4 size, the cost will actually be higher for thermal printing.

Sounds like ink-less printing is the way to go. Interesting article.