Expanding the product range and becoming more efficient at producing core products are key goals for most ambitious print companies. We recently put these goals into action with an investment in ‘cutting edge’ technology that ticks all the boxes in one hit.

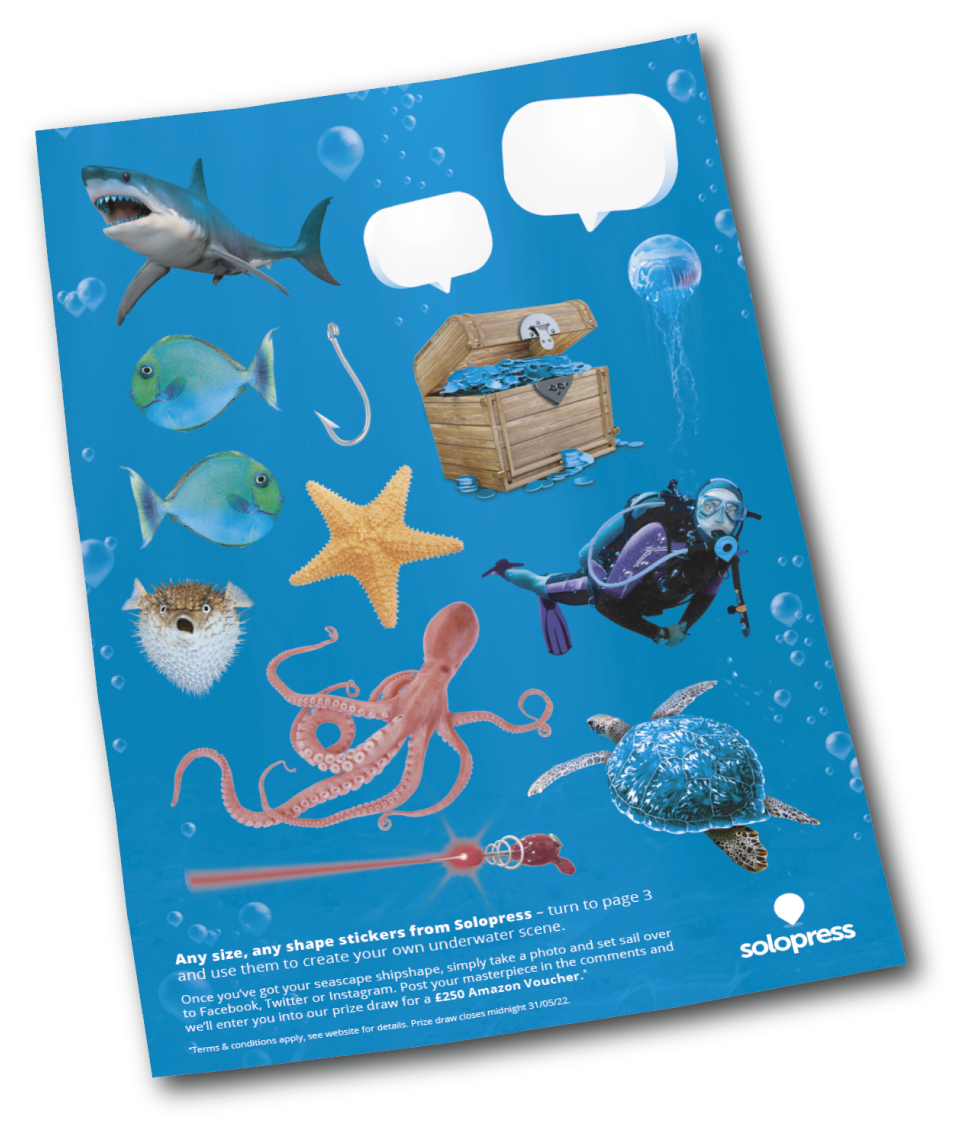

By acquiring the UK’s first Motioncutter 23 system through Konica Minolta, we managed simultaneously to upgrade the way we produce standard Labels, and as a result, introduced Custom Shape Stickers as a new product. The outstanding capabilities of the Motioncutter machine aren’t limited to kiss-cutting Stickers, however, and the acquisition opens up a sea of possibilities for us.

A cut above others

We installed the new machine in December of last year, and after a period of operator training and equipment testing, the Motioncutter 23 system was up and running earlier this year. The state-of-the-art laser cutter was put through its paces producing our existing range of standard-size Stickers. However, it wasn’t long before the Motioncutter was being used to produce a newly released product of ours: Custom Shape Stickers.

Small businesses, big benefit

This new capability for custom shape print products is great news for customers of all sizes, but the Motioncutter is especially economical for short runs. That makes it ideal for small businesses, as well as resellers serving that market.

In recent years, there has been an undeniable spike in new small businesses that lean heavily on a very personal and unique branding approach. This has been particularly evident in the area of food and drink, where artisanal and speciality products have been brought to market on the back of their individuality and quirky branding.

We responded to this trend in the spring of last year when we expanded our range of Label stocks to accommodate food and drink producers better. This range now includes materials that cope with moisture, heat and deep freeze, as well as meeting safety standards that allow for direct contact with foodstuffs.

Producers of this type value individuality, so a unique Custom Shape Sticker for their product is likely to hold great appeal. That’s just one sector among many that have seen a hike in demand for short runs of highly personalised labelling on a quick turnaround.

Wholesale improvements

It’s not just end-users that stand to benefit from our newfound print capabilities. Many print shops and resellers would understandably struggle to justify dropping £300,000 on a specialist piece of kit like the Motioncutter. It’s these businesses who are now able to partner with us as a supplier for this particular type of product. This way, if you partner with us, you can expand your offering to include laser-cut print items without any capital expenditure.

Our Managing director, Simon Cooper, welcomes the opportunity to develop partnerships with resellers in this way, saying: ‘We are looking forward to supporting trade partners that are looking to introduce laser-cut Stickers and other products.

‘We welcome any opportunity to speak directly with them to discuss the creation of sample packs, white label packaging and any other area where we could support them as they incorporate these new products into their catalogues.’

This is encouraging news for any business looking for a wholesale printer that is equipped to supply laser-cut products.

Boom time

So, our cutting-edge machine is here, but what led us to this point? The story of how we came to invest in this technology started by observing how well the category of common or garden standard shape Labels was performing.

According to Simon, ‘While demand for most products was understandably subdued during the pandemic, demand for Stickers and Labels never went away. In fact, it actually rose, and shows no signs of slowing.’

At that time, however, without any in-house label cutting equipment, production had become something of a pinch point for us.

A sticky situation

Up to this point, we were completely reliant on pre-cut Label stocks. In order to maintain a competitive range of Stickers, we were obliged to hold a vast stock of these Labels in every size, shape and material.

The laborious task of scanning shelf after shelf to retrieve the correct Label for each job would waste valuable staff hours, plus this comprehensive Label library was taking up precious square footage.

Printing onto pre-cut Label sheets also came with quality control issues. If alignment were to drift during a run, content could stray out of bounds, resulting in costly reprints and unwelcome waste of time, ink and materials.

With a steady rise in demand for Labels, along with customer research that we conducted, it was enough to convince the powers that be, that improving efficiency in this area should be a focus for us. The solution that would bring greater dynamic control over Label production would come in the form of our innovative Motioncutter machine.

Overkill or opportunity?

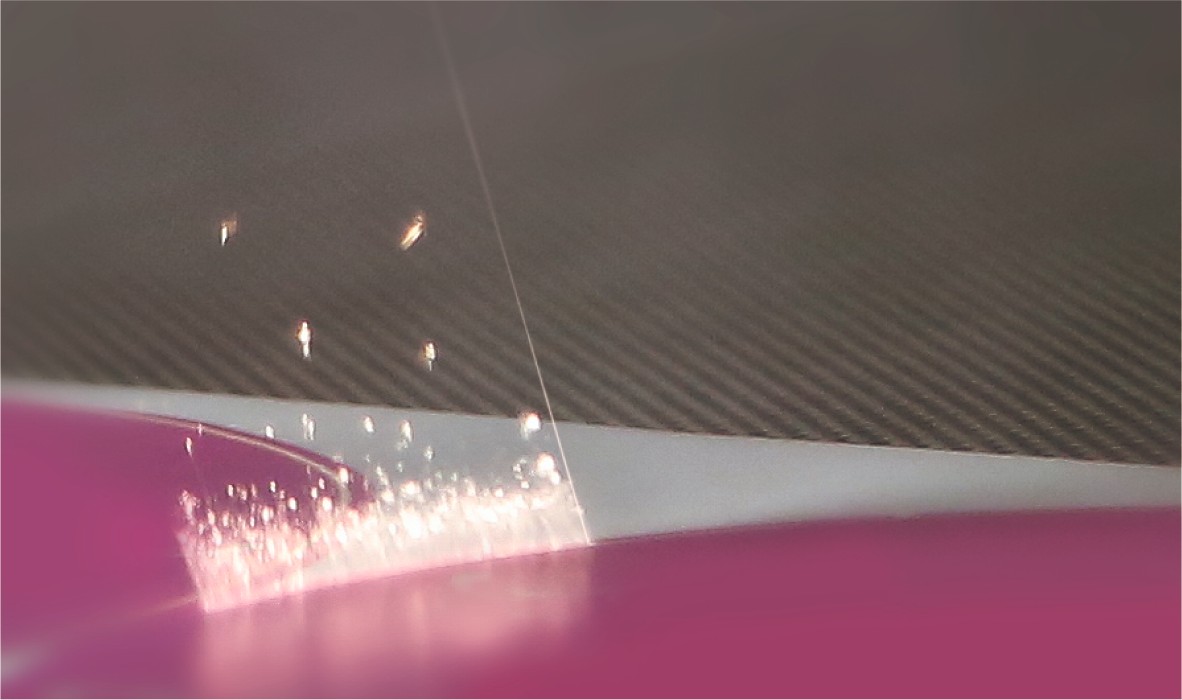

We needed the ability to cut Stickers to order, and the answer was to invest in the Motioncutter 23 system. At first glance, it seems that we bought a sledgehammer to crack a nut! And not just any sledgehammer – a £300,000 state-of-the-art, digital, high-speed laser sledgehammer!

It is a machine with tremendous technical capabilities that would be seriously underused were it to be just utilised to cut out circle and rectangle Labels. But Simon looks at it this way:

‘So great are the time and cost savings represented by its cutting capability, that the Motioncutter will recoup the capital expenditure we invested within 18 months. And that is through use on existing Label products alone.’

By merely taking over the production of our current Label offering and eliminating the need for pre-cut stock, this incredible machine essentially pays for itself. The fact that it also opens a vast opportunity for new laser-cut products is a significant bonus. In this light, the decision to buy the very best tool for the job starts to make a lot of sense.

A guiding hand

With no additional cost, effort or make-ready time, the Motioncutter is now tasked with producing kiss-cut stickers that follow cutter guides prescribed by customer-supplied artwork.

This puts you, the customer, in control to make any shape of Sticker possible. We’re making innovations in this area too.

To help our customers get the most from this new technology, we’re creating a unique solution to make it easier for you to provide your artwork. As part of the online proofing process we have at Solopress.com, a tool will scan your artwork and auto-generate a cutter guide for the laser to follow.

The cutter guide is then instantly presented to you for your approval before the job goes into production. This is efficient as it saves you time and avoids the need for you to create the cutter guide yourself and supply it as a separate layer. As far as we know, we’re the only UK printer offering this service to our customers.

Simple pricing, epic proportions

We’ve also transformed our pricing as a result. Instead of paying per Sticker for off-the-peg Labels, you can pay per sheet, regardless of the number of stickers our cutter guide determines.

So, if you order an A4 sheet of Stickers, whether the artwork features one large sticker or 50 small ones, the cost will be unaffected. Another positive by-product of this method of production is the nearly limitless options it allows in terms of Sticker sizes.

Label dimensions are limited only by the dimensions of the sheet being printed on, the theoretical maximum being 530 x750 mm, which is the largest that could fit through our machine.

Barely scratching the surface

Beyond the introduction of Custom Shape Stickers, we have ambitious plans to roll out further laser-cut products throughout 2022.

According to Simon, the Motioncutter is likely to be put to work on invitations, bespoke presentation folders and other speciality products. Look out for cut-out options on Brochures that could allow customers to create effects, just like the one we achieved when we were on the front cover of the monthly, Print Solutions magazine.

But custom shapes and cut-out areas still barely scratch the surface of what is possible through this remarkable technology! The potential for engraving, for example, can be harnessed in many ways, such as removing areas of colour or coating from pre-printed or laminated substrates or creating texture on thicker substrates.

The accuracy with which the laser cuts and perforates means it’s capable of fine filigree work and cut-out text. Software capabilities enable mass personalisation, so each piece could feature a specific name or message cut out or engraved into it.

All of these techniques present exciting opportunities that we can’t wait to explore. We look forward to discovering what the future holds for our Motioncutter and unlocking its potential. More importantly, we’re thrilled to see the endless possibilities it presents our customers and the new opportunities it gives you to make incredible designs and products.